In order to improve the accuracy of the machine tool, sometimes we need to add a full closed loop to the machine tool, which is to add feedback from a grating ruler. Of course, there are many types of grating rulers, such as Heidelberg, Farge, and so on. When configuring a full closed loop grating ruler, we need to know the specific data below in order to debug the machine tool

1. Model of grating ruler

2. Number and connection sequence of grating rulers for machine tool configuration

The specific setting of the grating ruler can be roughly divided into two steps. The first step is to set the FSSB. The second step is to set the position feedback and transmission ratio related parameters

The following is a case study of a machine tool for relevant settings, which you can refer to

Machine configuration X Y Z A C SP, where the spindle is a simulated spindle

一、Set FSSB parameters

How to Add Full Closed Loop to Fanuc System?

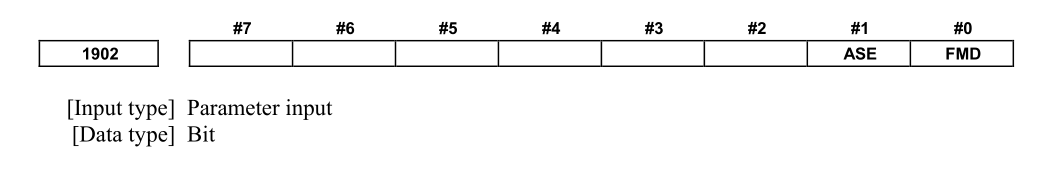

SET 1902#0 TO 1

#0 FMD The FSSB setting mode is:

0: Automatic setting mode.

(When the relationship between an axis and amplifier is defined on the FSSB settingscreen, parameter No.1023, bit 0 of parameter No.2013, parameter No.3717, bit 4 of

parameter No.11802 and parameters 24000 to 24103 are automatically set.

1: Manual setting 2 mode.

(parameter No.1023, bit 0 of parameter No.2013, parameter No.3717, bit 4 ofparameter No.11802 and parameters 24000 to 24103 are to be manually set.)

二、Setting 24000 PARAMETERS OF FSSB

24000—24031 ATR value corresponding to slave 01 on first FSSB line

1001 to 1046, 2001 to 2016, 3001 to 3004, 1000

Each of these parameters sets the value (ATR value) of the address translation tablecorresponding to each of slave 1 to slave 32 on first FSSB line (first optical connector).

The slave is a generic term for servo amplifiers, spindle amplifiers and separate detectorinterface units connected via an FSSB optical cable to the CNC. Numbers 1 to 32 are assigned to slaves, with younger numbers sequentially assigned to slaves closer to the

CNC. A 2-axis amplifier consists of two slaves, and a 3-axis amplifier consists of three slaves. In each of these parameters, set a value as described below, depending on whether theslave is an amplifier, separate detector interface unit, or nonexistent.

• When the slave is a servo amplifier:

Set the axis number of a servo amplifier to allocate (value set with parameter No.1023) plus 1000.

• When the slave is a spindle amplifier:

Set the spindle number of a spindle to allocate (value set with parameter No. 3717)plus 2000.

• When the slave is a separate detector interface unit:

Set 3001, 3002, 3003, and 3004, respectively, for the first (one connected nearest to

the CNC), second, third, and fourth separate detector interface units.

• When the slave is nonexistent: Set 1000.

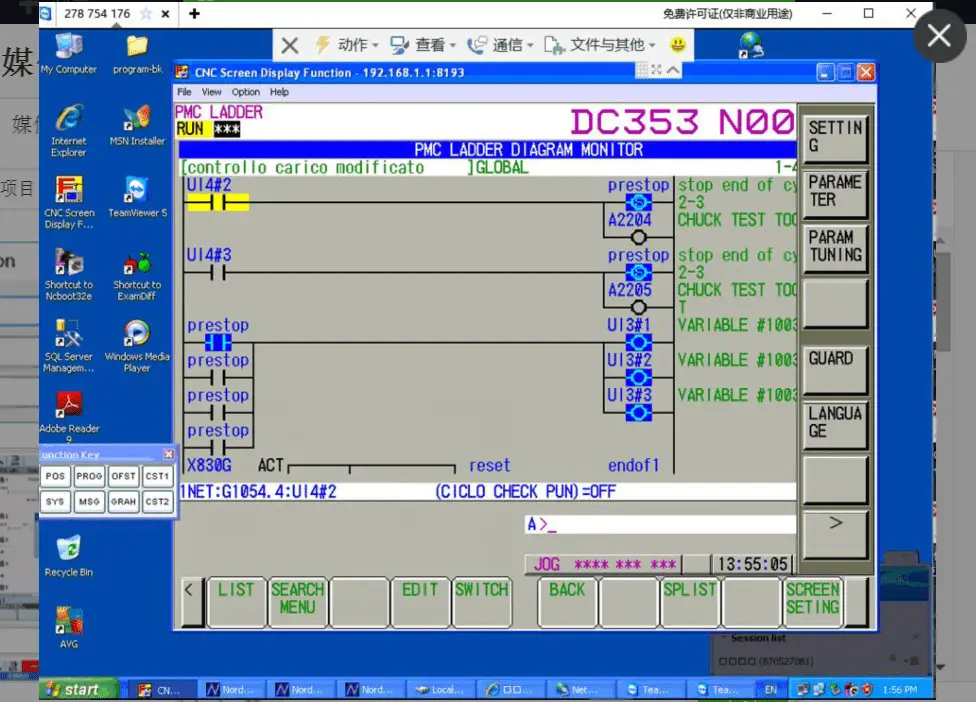

Example of axis configuration and parameter settings

![图片[2]-How to Add Full Closed Loop to Fanuc System? - FANUC CNC-FANUC CNC](https://www.share5.cn/wp-content/uploads/2024/04/1713965838812.png)

For this Machine:

24000 1001

24002 1002

24003 1003

24004 1004

24005 1005

24006 3001 SDU

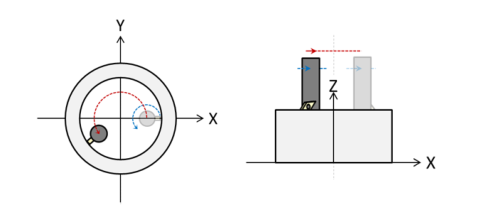

三、Setting 24096 TO 24103

Connector number for the first or ninth separate detector interface unit

Set a connector number for the connector to which a separate detector interface unit isattached if the separate detector interface unit is to be used. The following table lists the necessary settings. Be sure to specify 0 for connectors not in use.

![图片[3]-How to Add Full Closed Loop to Fanuc System? - FANUC CNC-FANUC CNC](https://www.share5.cn/wp-content/uploads/2024/04/1713966083711.png)

![图片[4]-How to Add Full Closed Loop to Fanuc System? - FANUC CNC-FANUC CNC](https://www.share5.cn/wp-content/uploads/2024/04/1713966125006.png)

暂无评论内容